Carbon Steel Hex Bolt Din 933

| Products name | CARBON STEEL HEX BOLT DIN 933/ISO4017 |

| Standard | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| Giredhi | Simbi Giredhi: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Kupedza | Zinc (Yero, Ichena, Bhuruu, Nhema), Hop Dip Galvanized(HDG),Black Oxide, Geomet,Dacroment,anodization,Nickel yakapfekwa,Zinc-Nickel yakapfekwa |

| Production Process | M2-M24: Kutonhora Kunotonhora, M24-M100 Kupisa Kugadzira, Machining uye CNC yeCustomized fastener |

| Customized Zvigadzirwa Kutungamira nguva | 30-60 mazuva, |

| Yemahara Samples ye standard fastener | |

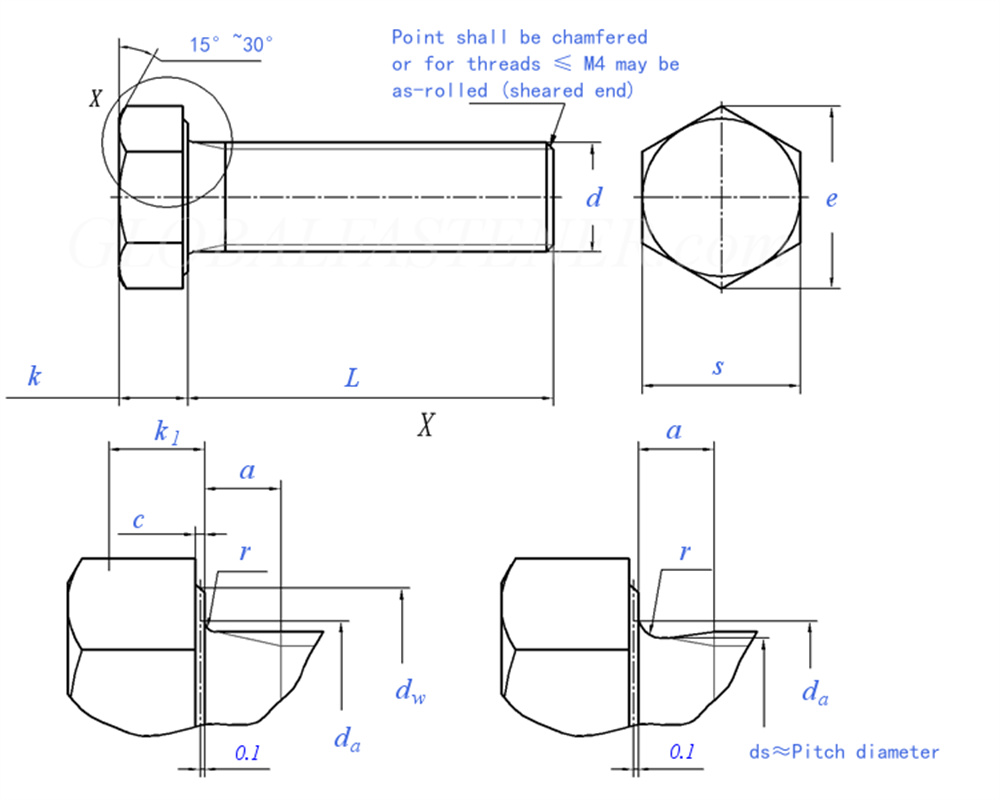

| Screw Thread | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| a | max | 1.05 | 1.2 | 1.35 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | 3 | 4 | 4.5 | 5.3 | |

| min | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | ||

| c | max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| dw | Giredhi A | min | 2.27 | 3.07 | 4.07 | 4.57 | 5.07 | 5.88 | 6.88 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| Giredhi B | min | 2.3 | 2.95 | 3.95 | 4.45 | 4.95 | 5.74 | 6.74 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | Giredhi A | min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| Giredhi B | min | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| k | Nominal Saizi | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| Giredhi A | max | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| min | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| Giredhi B | max | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| min | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Giredhi A | min | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| Giredhi B | min | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | max=saizi yezita | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Giredhi A | min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| Giredhi B | min | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Screw Thread | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Pitch | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| a | max | 6 | 6 | 7.5 | 7.5 | 7.5 | 9 | 9 | 10.5 | 10.5 | 12 | 12 | 13.5 | |

| min | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | ||

| c | max | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| min | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | max | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| dw | Giredhi A | min | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| Giredhi B | min | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | Giredhi A | min | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| Giredhi B | min | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| k | Nominal Saizi | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| Giredhi A | max | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| min | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Giredhi B | max | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| min | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | Giredhi A | min | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| Giredhi B | min | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | min | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | max=saizi yezita | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Giredhi A | min | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| Giredhi B | min | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Screw Thread | (M45) | M48 | (M52) | M56 | (M60) | M64 | ||||||||

| P | Pitch | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | |||||||

| a | max | 13.5 | 15 | 15 | 16.5 | 16.5 | 18 | |||||||

| min | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | ||||||||

| c | max | 1 | 1 | 1 | 1 | 1 | 1 | |||||||

| min | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | ||||||||

| da | max | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 | |||||||

| dw | Giredhi A | min | - | - | - | - | - | - | ||||||

| Giredhi B | min | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 | |||||||

| e | Giredhi A | min | - | - | - | - | - | - | ||||||

| Giredhi B | min | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 | |||||||

| k | Nominal Saizi | 28 | 30 | 33 | 35 | 38 | 40 | |||||||

| Giredhi A | max | - | - | - | - | - | - | |||||||

| min | - | - | - | - | - | - | ||||||||

| Giredhi B | max | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 | |||||||

| min | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 | ||||||||

| k1 | Giredhi A | min | - | - | - | - | - | - | ||||||

| Giredhi B | min | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 | |||||||

| r | min | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 | |||||||

| s | max=saizi yezita | 70 | 75 | 80 | 85 | 90 | 95 | |||||||

| Giredhi A | min | - | - | - | - | - | - | |||||||

| Giredhi B | min | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | |||||||

Features uye Benefits

Carbon Steel Hex Bolt Din 933: Mhinduro kune Zvako Kutsanya Zvido

Kana zvasvika pakutsanya, iwe unoda mhinduro yakasimba, yakavimbika uye iri nyore kuisa. Carbon Steel Hex Bolt Din 933 inokwevera ese mabhokisi ekurudyi nekupa bhaudhi yakasimba uye inoshanda zvakasiyana-siyana iyo inogona kushandiswa pane dzakasiyana siyana dzekushandisa.

Yakagadzirwa kubva kumhando yepamusoro kabhoni simbi, bhaudhi iyi yakagadzirirwa kutsungirira nharaunda dzakaoma, kushushikana kwakanyanya uye mitoro inorema. Musoro une hexagonal unopa yakachengeteka uye yakasimba kukwana, nepo shinda ichibvumira kuisirwa nyore uye kubvisa.

Kuyera 6mm kusvika 100mm pakureba, bhaudhi iyi inowanikwa muhukuru hwakasiyana kuti ienderane nemapurojekiti akasiyana uye zvinodiwa. Kunyangwe iwe uri kuvaka muchina, kumisa dhizaini kana yekumisikidza michina pamwechete, iyi bhaudhi inopa simba uye kusimba kwaunoda kuti basa riitwe.

Uyezve, Carbon Steel Hex Bolt Din 933 iri nyore kuchengetedza uye haina kushata nyore nekufamba kwenguva. Izvi zvinoreva kuti iwe unogona kuvimba nekubudirira kwayo kwemakore mushure mekuiswa.

Kune avo vanotsvaga bhaudhi iyo inokwanisika uye yemhando yepamusoro, iyi kabhoni simbi bhoti isarudzo yakakwana. Kwete chete inobvisa kudiwa kwezvinodhura uye zvakaoma zvekumisa mhinduro, asi zvakare zviri nyore kuisa nekubvisa, zvichikuchengetedza iwe yakakosha nguva uye kushanda nesimba.

Muchidimbu, Carbon Steel Hex Bolt Din 933 ndeye yakavimbika uye inoshanda yekumisa mhinduro inogona kushandiswa muhuwandu hwekushandisa. Yakagadzirirwa kusimba kwakanyanya uye nyore kushandisa, zvichiita kuti ive yekuenda-kune sarudzo kune mainjiniya, vavaki uye DIY vanofarira zvakafanana. Vimba neCarbon Steel Hex Bolt Din 933 kuti ikupe mhinduro inokwenya mabhokisi ese, zvisinei kuti uri kushanda pairi chirongwa chipi.