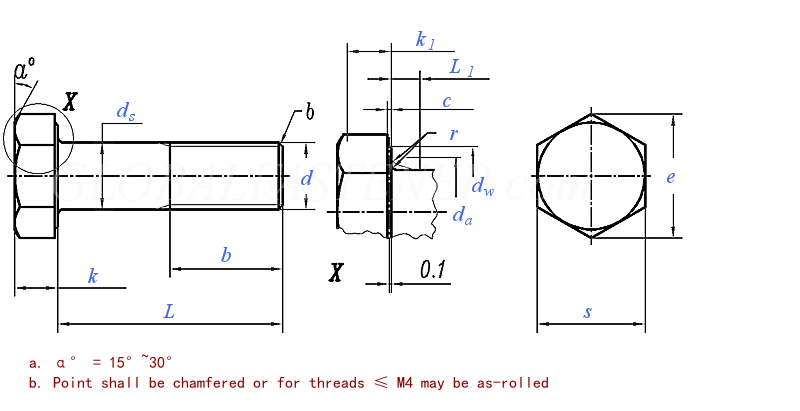

Carbon Steel Hex Bolt Din 931/iso4014

| Products name | CARBON STEEL HEX BOLT DIN 931/ISO4014 |

| Standard | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| Giredhi | Simbi Giredhi: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A, A325, A490, |

| Kupedza | Zinc (Yero, Ichena, Bhuruu, Nhema), Hop Dip Galvanized(HDG),Black Oxide, Geomet,Dacroment,anodization,Nickel yakapfekwa,Zinc-Nickel yakapfekwa |

| Production Process | M2-M24: Kutonhora Kunotonhora, M24-M100 Kupisa Kugadzira, Machining uye CNC yeCustomized fastener |

| Customized Zvigadzirwa Kutungamira nguva | 30-60 mazuva, |

| Yemahara Samples ye standard fastener | |

| Screw Thread | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | Pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| b | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125<L≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L>200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| min | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | max=saizi yezita | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| Giredhi A | min | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | |

| Giredhi B | min | 1.35 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 4.7 | 5.7 | 6.64 | 7.64 | 9.64 | 11.57 | |

| dw | Giredhi A | min | 2.54 | 3.34 | 4.34 | 4.84 | 5.34 | 6.2 | 7.2 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| Giredhi B | min | 2.42 | 3.22 | 4.22 | 4.72 | 5.22 | 6.06 | 7.06 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | Giredhi A | min | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| Giredhi B | min | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| L1 | max | 0.6 | 0.8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Nominal Saizi | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| Giredhi A | max | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| min | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| Giredhi B | max | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| min | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | Giredhi A | min | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| Giredhi B | min | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | min | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | max=saizi yezita | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| Giredhi A | min | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| Giredhi B | min | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Hurefu hwe Thread b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Screw Thread | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | Pitch | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125<L≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L>200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | max | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| min | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | max | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| ds | max=saizi yezita | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| Giredhi A | min | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | - | - | - | - | - | - | |

| Giredhi B | min | 13.57 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | |

| dw | Giredhi A | min | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| Giredhi B | min | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | Giredhi A | min | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| Giredhi B | min | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| L1 | max | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Nominal Saizi | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| Giredhi A | max | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| min | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| Giredhi B | max | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| min | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | Giredhi A | min | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| Giredhi B | min | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | min | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | max=saizi yezita | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| Giredhi A | min | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| Giredhi B | min | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Hurefu hwe Thread b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Screw Thread | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | Pitch | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | L≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125<L≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L>200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | max | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| min | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

|

|

|

|

|

| ||

| da | max | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | max=saizi yezita | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| Giredhi A | min | - | - | - | - | - | - |

|

|

|

|

|

| |

| Giredhi B | min | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 |

|

|

|

|

|

| |

| dw | Giredhi A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Giredhi B | min | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 |

|

|

|

|

|

| |

| e | Giredhi A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Giredhi B | min | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 |

|

|

|

|

|

| |

| L1 | max | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Nominal Saizi | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| Giredhi A | max | - | - | - | - | - | - |

|

|

|

|

|

| |

| min | - | - | - | - | - | - |

|

|

|

|

|

| ||

| Giredhi B | max | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

|

|

|

|

|

| |

| min | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 |

|

|

|

|

|

| ||

| k1 | Giredhi A | min | - | - | - | - | - | - |

|

|

|

|

|

|

| Giredhi B | min | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 |

|

|

|

|

|

| |

| r | min | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | max=saizi yezita | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| Giredhi A | min | - | - | - | - | - | - |

|

|

|

|

|

| |

| Giredhi B | min | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 |

|

|

|

|

|

| |

| Hurefu hwe Thread b | - | - | - | - | - | - |

|

|

|

|

| |||

Features uye Benefits

Carbon Steel Hex Bolt Din 931/iso4014 ndeyemhando yepamusoro yekusimbisa mhinduro inogadzirwa kubva kune yakavimbika kabhoni simbi zvinhu. Iyo inouya neine hexagonal musoro chimiro chakagadzirirwa kuti ive yakanyatsokwana kune wrench kana socket, zvichiita kuti zvive nyore kuomesa kana kusunungura pasina kutsvedza. Din 931 uye iso4014 zviyero zvinowedzera kuve nechokwadi chayo, kusimba, uye kuvimbika mumashandisirwo akasiyana siyana.

Iyi mhando yehex bolt ine shank yakarukwa iyo ine zvishoma kana yakazara shinda inobvumira yakachengeteka uye yakasimba fit kana uchibatanidza zviviri kana kupfuura zvikamu. Inowanzo shandiswa mumashandisirwo anosanganisira michina, zvishandiso, uye zvimiro zvinoda simba repamusoro, chengetedzo, uye kurongeka chaiko.

Carbon simbi, ferrous metal alloy inoumbwa zvakanyanya nesimbi uye kabhoni, isarudzo yakanaka kwazvo yerudzi urwu rwebhaudhi nekuda kwesimba rayo, kusimba, uye kuramba kupfeka uye kubvaruka. Saka nekudaro, Carbon Steel Hex Bolt Din 931/iso4014 inogona kumira nharaunda dzakaomarara, kudzvanywa kwepamusoro, uye tembiricha yepamusoro pasina kurasikirwa nekusimba kwayo kana kuora. Zvakare, ivo vanouya mukupedzisa kwakasiyana senge black oxide, galvanized, uye zinc yekudzivirira kubva mukuora.

Iko kuita kwakasiyana-siyana uye kuvimbika kweCarbon Steel Hex Bolt Din 931/iso4014 inoita kuti ive imwe yeanonyanya kufarirwa fasteners muindastiri. Inowanikwa mumasikirwo akasiyana-siyana kuti igare zvakasiyana-siyana zvekushandisa zvinodiwa, uye iyo hexagonal chimiro inovimbisa kuisirwa nekubvisa nyore. Kunyangwe iwe uri kushanda purojekiti yeindasitiri, mota application, kana kuvandudza imba, iyi hex bolt isarudzo yakavimbika.

Mukupedzisa, Carbon Steel Hex Bolt Din 931/iso4014 chikamu chakakosha chechero kuvaka, kugadzira, kana kugadzirisa mapurojekiti anoda yakasimba, yakachengeteka, uye yakavimbika fastener. Simba rayo rakanakisa, kusimba, uye corrosion kuramba inoita kuti ive sarudzo yakanaka kune akasiyana maapplication. Saka, usazeza kusarudza iyi hex bolt yepurojekiti yako.